What is MOLLE? How This System Revolutionized Tactical Gear

Posted by Simon on Jan 22nd 2025

What is MOLLE?

If you’re asking “What is MOLLE?” you’re probably not from the military or tactical industries. But that’s okay—MOLLE has been steadily making its way into the civilian world in recent years, especially in outdoor, survival, and adventure gear.

MOLLE stands for Modular Lightweight Load-carrying Equipment, a system designed to enhance gear customization, organization, and efficiency. Introduced in the late 1990s, MOLLE was developed for the U.S. military to replace the older ALICE (All-Purpose Lightweight Individual Carrying Equipment) system. The MOLLE system is built on a foundation of PALS webbing (Pouch Attachment Ladder System), which consists of horizontal rows of heavy-duty webbing sewn onto gear like backpacks, tactical vests, and belts. This webbing allows users to securely attach pouches, tools, and other modular accessories using straps or clips, creating a flexible, fully customizable loadout.

Check out our MOLLE-compatible pouches and DIY molle panels for examples of how you can optimize your setup (You can now add MOLLE anywhere on your gear or prototype with this pre-made MOLLE panel.).

While there’s no official record of the inspiration behind MOLLE, it’s likely influenced by early webbing loops and attachment slits that were often found on civilian backpacks. These features, which allowed for external attachments like water bottles or gear patches, might have served as a precursor to the MOLLE system. Even today, some civilian backpacks still include similar designs.

Thanks to its versatility and functionality, MOLLE has become a staple in military, law enforcement, and first responder communities. It has also started to benefit the civilian market, making outdoor backpacks, laptop bags, and even school bags more customizable and practical for everyday use.

Explore our collection of MOLLE-compatible products to customize your gear and make it work for you.

Whether you’re part of the tactical world or just exploring its benefits, understanding MOLLE is the first step in optimizing your gear setup.

Here is the Standard:

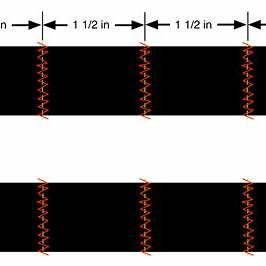

MOLLE uses the PALS webbing system, which consists of rows of 1-inch-wide webbing spaced 1 inch apart, with stitching reinforcement every 1.5 inches. This standard ensures compatibility across all MOLLE gear, making it universally reliable.

If you’re unfamiliar with the layout, here’s a helpful visual diagram or plan to illustrate the MOLLE and PALS webbing standard.

Modern Laser-Cutting: A Game-Changer with New Challenges

The introduction of laser-cutting technology has revolutionized the design and functionality of MOLLE and PALS systems. By allowing for precise, seamless cuts in modern heavy-duty materials, this technology has opened up new possibilities for durability, and streamlined gear. However, these advancements have also introduced some challenges.

While this process saves on production (traditional webbing with bar tacks is very time-consuming to produce and requires a lot of material), it also tends to retain less water and dust. However, the material itself is slightly heavier than traditional webbing.

One significant change is the reduction in the size of openings in the PALS webbing. Traditional stitched webbing often had more flexibility, while laser-cut designs, due to the nature of the material and cutting process, create tighter openings. This change makes the gear more stable and reduces unwanted movement, a big advantage for mission-critical situations.

However, hard plastic accessories designed for the original PALS webbing—such as clips, mounts, and holders—often no longer fit into these tighter openings without significant force. This has led to compatibility issues for users attempting to integrate older equipment with newer gear.

Innovative Solutions from Industry

Companies have taken different approaches to address these challenges:

- Carcajou Tactical: This pioneering Canadian company has adopted an "in-between" solution, offering laser-cut gear with slightly larger openings to balance compatibility and stability.

- Down East Innovation: This company has designed a new generation of products, such as the FASTMAG Gen 5, specifically engineered to fit these tighter laser-cut webbing systems, ensuring seamless integration and usability with modern tactical gear.

References: